In the right hands, Ground Penetrating Radar (GPR) offers the safest, fastest, and most comprehensive non-destructive subsurface scanning option for a wide range of applications within construction and engineering.

From mapping bedrock and utilities tens of feet deep, to identifying and locating rebar, conduits and post-tension cables in concrete slabs, GPR has a huge number of applications across a wide range of industries.

Its versatility makes it one of the most useful tools in engineering, construction, archaeology, geosciences, and many other fields.

Paired with advanced data processing software, Ground Penetrating Radar is able to bring out the hidden targets in a clarity that is leaps and bounds ahead of other methods used in similar scenarios.

One of those uses we are going to focus on further below is subsurface utility engineering (SUE).

What is GPR?

Ground Penetrating RADAR (Radio Detection And Ranging) consists of a transmitting antenna coupled with a receiving antenna. Electromagnetic waves emitted by the antenna penetrate the ground and reflect off objects below the surface. By measuring the travel time for the electromagnetic waves to travel through the ground, reflect off the target and return to the surface, an estimate of the shape, size, and depth of a target can be made.

The strength, or amplitude, of the reflected wave is determined by the contrast in the dielectric permittivity and the conductivity of the two materials. To put this into context, a wave that moves from dry sand (dielectric of 5) to wet sand (dielectric of 30 and higher conductivity) will produce a strong reflection, while moving from dry sand (5) to limestone (7) will produce a relatively weak reflection.

Using GPR in Subsurface Utility Engineering (SUE)

Subsurface Utility Engineering (SUE) is the process of locating and mapping existing underground infrastructure, often used to create as-built drawings for future projects.

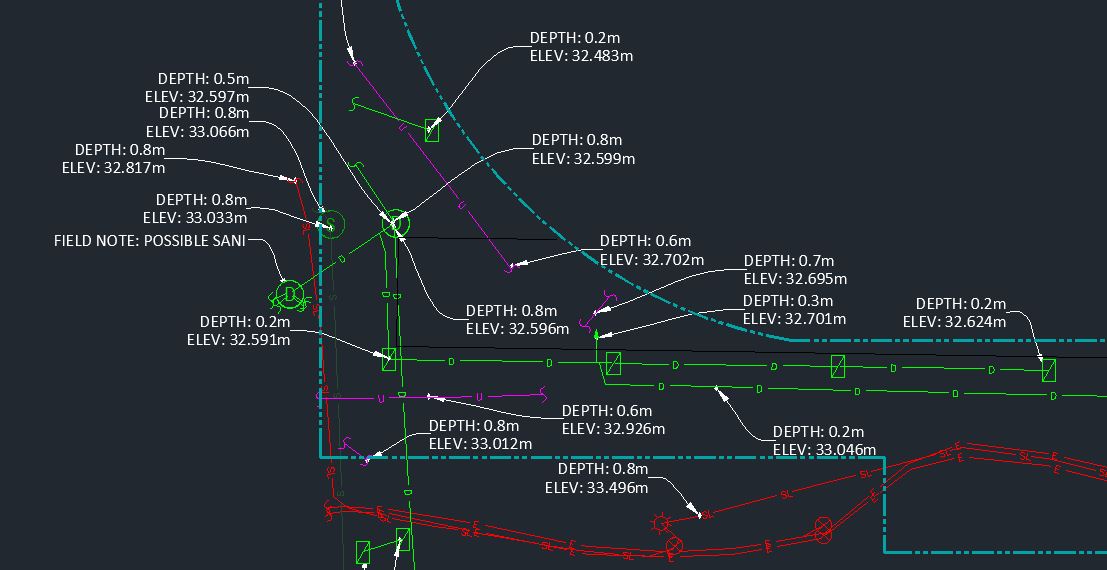

Information gathered on the subsurface utilities located (utility nature, depth, location, orientation, material, dimensions and ownership) during the field survey are recorded and accurately georeferenced using survey grade GPS and total station.

The primary use of GPR allows you to quickly gather data about the subsurface that cannot always be found from other methods. For instance locating non conductive materials e.g. Polyvinyl chloride (PVC) can also precisely find the edge of underground duct banks. The data can either be interpreted in real time by a skilled technician or it can be collected and processed back in an office. This method results in a reduced site time and therefore reduced costs, as data can be collected at up to highway speeds.

Whether the work involves trenching, excavating, or drilling, implementing SUE is key to ensuring the successful outcome of a project in relation to the management of risks associated with the underground utility infrastructure. The locate work performed is governed by the ASCE 38-22 standards that provides a benchmark to show the integrity and quality of utility data collected.

GPR data can be collected at up to highway speeds

GPR data can be collected at up to highway speeds

Reducing risk and saving money

Timely Subsurface Utility Engineering reduces project risk and saves money. The Ontario Sewer and Watermain Contractors Association recently commissioned the University of Toronto to investigate the practice of using SUE on large infrastructure projects. The study determined that the average return rate for each dollar spent on SUE services was $3.41 (the full paper can be found here).

The advantages of Subsurface Utility Engineering are huge in the construction industry. Having this valuable information on demand is critical for the pre-design phase of any project involving ground disturbance. Not only does it aid in project safety by avoiding risk resulting from damaged underground utilities, it also mitigates costs associated with utility repair, unanticipated development redesign, project delays, and various other unforeseen conflicts.

The SUE Process

A SUE project is classified by four quality levels with the objective to improve the reliability of the data presented.

The highest quality level (quality level A) involves daylighting the utility once located to visually confirm the details of the structure as well as to allow for the most accurate horizontal and vertical positional measurements to be collected.

The majority of projects can reduce daylighting costs by using quality level B data. This uses data from geophysical methods to find and map utility data. This level of accuracy is predominantly required where conflicts arise with the proposed development alignment. Locate results are then surveyed and drafted to produce a scaled drawing showing the horizontal and vertical location of the underground infrastructure along with additional details and characteristics of the utilities.

Lower levels of SUE (quality levels C and D) are more suited for areas surrounding the projected design where underground infrastructure does not interfere with the ground disturbance. The finished product of a SUE project contains all levels of data.

Results from this work are then delivered as a 3D CAD drawing ready to be incorporated into the design of the project. Subsurface Utility Engineering projects are reviewed and approved by a certified engineer to add assuritys to the work completed.

Completing a SUE project at a busy terminal

A popular BC Ferry Terminal initiated a project to fully understand the complexity of their underground infrastructure, within their 87,000 square meter zone, including a fueling station and a wastewater treatment plant (WWTP).

With this being a busy area, having an intense flow of traffic for at least 16 hours a day, it presented a few issues. Most notably, how the chosen locating company would manage to cover the heavy traffic areas with minimal disruption. Rigorous planning can only get you so far when the amount of ground work required is so vast.

This is where GPR locating really benefits the project. Using the GSSI 400Mhz antenna coupled with the SIR4000 the technician is able to cover at least 800 square meters per hour, split into short intervals allowing for fairly continuous traffic flow. The reduced disruption would allow for ferry timetables to run closer to typical schedules, ensuring no knock-on effect for travellers.

Real time GPR data is produced and analysed on site, allowing for immediate reworking if necessary, further reducing the potential for unexpected project extensions.

The result of which was a very comprehensive report clearly outlining the terminal’s infrastructure, including some information of which the Ferry Terminal had never been aware of. This allowed them to suitably plan their future maintenance and planned upgrades with reduced risk and an ability to comprehensively plan before breaking ground.

Conclusion

The versatility of Ground Penetrating Radar when operated by trained technicians makes it one of the most comprehensive and efficient tools in engineering, construction and many other fields.

It is the hope of many in the industry that the method is more commonly used, to increase the safety of workers and the public, by raising the quality of data for services such as subsurface utility engineering. Utilizing GPR and SUE effectively will help save the industry both time and money by ensuring fewer project delays and costly repairs.